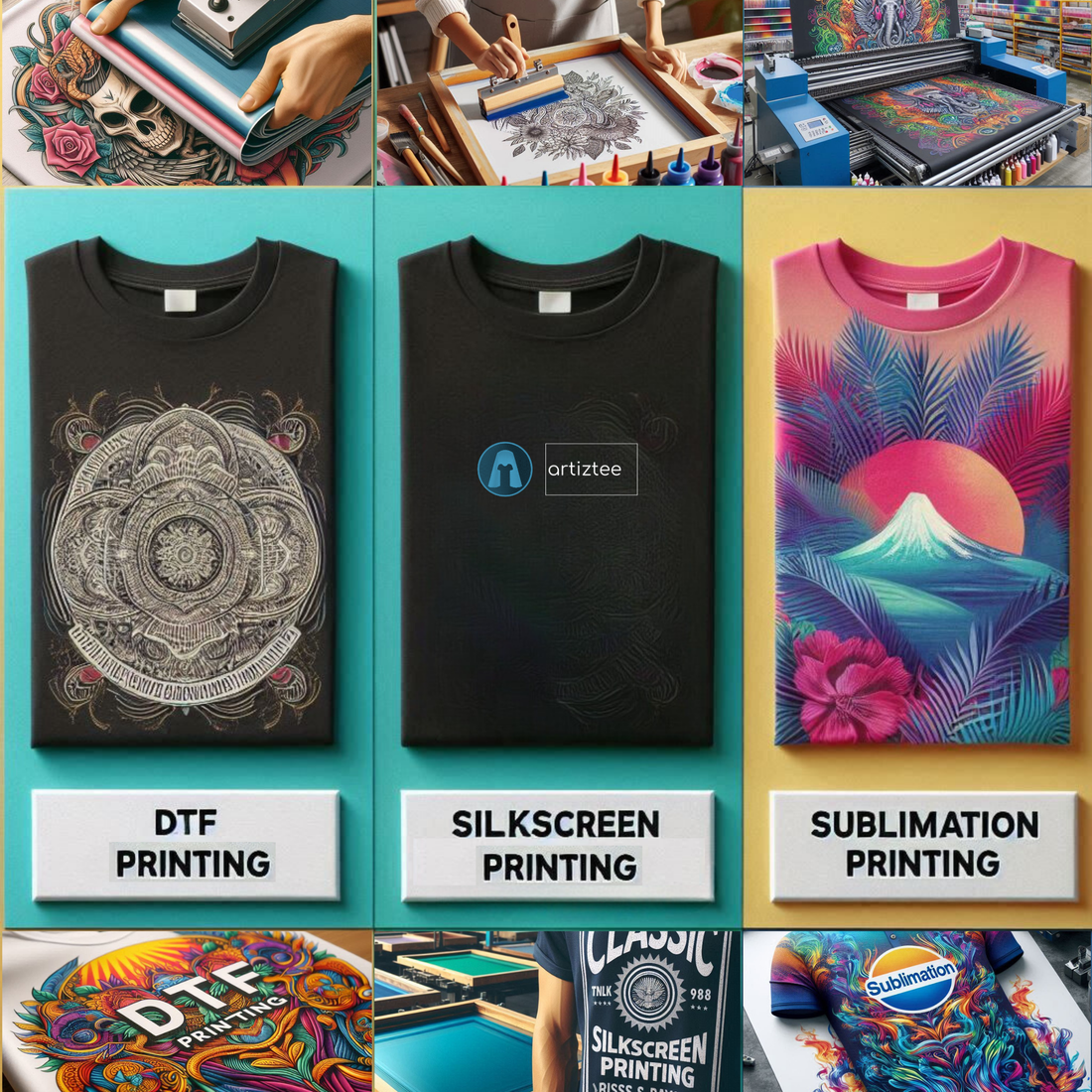

DTF Printing vs. Silkscreen Printing vs. Sublimation: Which Method is Best for Your Custom Apparel?

Share

When it comes to creating custom apparel, the printing method you choose plays a critical role in the quality, durability, and overall look of the final product. Whether you're designing uniforms, polos, t-shirts, or other types of clothing, the printing technique can make all the difference in bringing your vision to life. Today, we’ll explore three popular printing methods: DTF printing (Direct-to-Film), Silkscreen printing, and Sublimation printing. We'll also help you decide which is best for your specific apparel needs, including different fabric types like cotton, polyester, and microfibre.

Understanding the Basics of DTF Printing, Silkscreen Printing, and Sublimation

Before we dive into which method is best for your custom apparel, let's start by understanding the basics of each printing technique:

-

DTF Printing (Direct-to-Film)

- DTF printing is a newer technology where designs are printed directly onto a special transfer film, then heat-pressed onto the fabric. Unlike other methods, DTF printing is highly versatile, allowing for detailed, high-quality images with vibrant colors.

-

Silkscreen Printing

- Silkscreen printing, also known as screen printing, is one of the oldest and most common printing methods. It involves using a stencil (or screen) to apply ink layer by layer to the fabric. This technique is ideal for bold, solid designs, especially for large batches.

-

Sublimation Printing

- Sublimation is a technique where the design is printed onto a special paper and then transferred to the fabric using heat. The dye turns into gas and becomes part of the fabric itself, making it a permanent, long-lasting print. This method works best on microfibre or polyester fabrics.

DTF Printing: The Versatile Choice

If you're looking for a printing method that works on a wide range of fabrics—including cotton, microfibre, polyester, and blends like a 60% cotton mix with 40% polyester—DTF printing is one of the most flexible options available. It offers a combination of vivid color, fine detail, and excellent durability.

One of the biggest advantages of DTF printing is that it doesn't require the fabric to be pre-treated. You can print on a wide variety of materials, whether you're customizing t-shirts, uniforms, or polo shirts. This flexibility makes DTF ideal for anyone looking to offer custom designs on both cotton-based and synthetic materials, including microfibre.

Another benefit of DTF printing is its ability to print complex designs with multiple colors or gradients. Unlike silkscreen printing, where each color needs a separate screen, DTF prints the entire design at once. This makes it great for intricate logos or artwork that require a high level of detail.

Pros of DTF Printing:

- Works on a wide variety of fabrics (cotton, polyester, microfibre, etc.).

- Ideal for complex designs with multiple colors.

- Good durability with vibrant colors.

- No pre-treatment required for fabric.

Cons of DTF Printing:

- Not as cost-effective for large batches.

- Can feel slightly thicker on the fabric compared to sublimation.

Silkscreen Printing: Best for Large Batches and Bold Designs

Silkscreen printing has been the go-to method for custom apparel for decades. If you're producing uniforms or large orders of polo shirts or t-shirts, this technique can be extremely cost-effective. Because silkscreen printing applies ink in thick, solid layers, it’s ideal for simple designs with fewer colors, such as company logos or team uniforms.

This method works best on cotton and cotton-blend fabrics. For example, a 60% cotton mix with 40% polyester is perfect for silkscreen printing, as the ink adheres well to the cotton fibers and creates a bold, lasting print. However, polyester fabrics and microfibre materials can also be printed using this method, but it requires specialized inks to ensure proper adhesion.

One major benefit of silkscreen printing is its ability to handle large orders efficiently. If you need to print hundreds or thousands of t-shirts or polos for an event, this is often the most economical choice. It’s also incredibly durable, with the ink sitting on top of the fabric, ensuring that your design will withstand multiple washes and long-term wear.

Pros of Silkscreen Printing:

- Best for large batches and cost-effectiveness.

- Durable, long-lasting prints.

- Works well on cotton and cotton-blend fabrics.

- Great for bold, simple designs.

Cons of Silkscreen Printing:

- Not ideal for complex designs with multiple colors.

- Requires a different screen for each color, increasing costs for colorful prints.

- Less flexibility with synthetic fabrics like polyester and microfibre.

Sublimation Printing: Perfect for Mircofibre/Polyester and Sportswear

When it comes to fabrics like polyester and microfibre, sublimation printing is often the top choice. Sublimation works best with synthetic fibers because the dye turns into gas and bonds with the fabric, creating a print that’s as durable as it is vibrant. This makes sublimation printing an excellent option for custom sportswear, uniforms, and polo shirts made from these materials.

One of the biggest advantages of sublimation is that the print becomes part of the fabric, so there’s no texture or raised surface. This means the design won’t crack, peel, or fade, even after repeated washing. For breathable, lightweight fabrics like microfibre, sublimation ensures that the garment retains its comfort and flexibility without compromising the design.

However, sublimation has its limitations when it comes to fabric choice. While it’s perfect for 100% polyester or microfibre, it doesn’t work well on natural fibers like cotton. If you're looking to print on a 60% cotton mix with 40% polyester, you may find that the design fades or doesn’t transfer as well, so it’s not the best option for cotton-based fabrics.

Pros of Sublimation Printing:

- Perfect for polyester and microfibre fabrics.

- The print becomes part of the fabric, so it doesn’t fade or crack.

- Ideal for sportswear, uniforms, and lightweight clothing.

- Vibrant colors and long-lasting durability.

Cons of Sublimation Printing:

- Doesn’t work well on cotton or cotton-blend fabrics.

- Limited to light-colored garments, as the ink is translucent.

- Can be more expensive for smaller batches.

Choosing the Right Method for Your Custom Apparel

When deciding between DTF printing, silkscreen printing, and sublimation for your custom apparel, the best option depends on the type of fabric, the complexity of your design, and the size of your order.

-

DTF Printing is your go-to if you need flexibility in fabric choice (including cotton, polyester, and microfibre) and want to create detailed, multi-colored designs. It's a great option for smaller orders or unique items like custom polo shirts or t-shirts.

-

Silkscreen Printing is ideal for large batches of uniforms, t-shirts, or polo shirts made from cotton or cotton-blend fabrics. It’s cost-effective for simple designs and ensures durability over time.

-

Sublimation Printing is best for polyester and microfibre garments, particularly for sportswear and active uniforms. If your clothing is made from synthetic fibers and you need a vibrant, permanent design, sublimation is your top choice.

Final Thoughts

At Artiztee, we understand that choosing the right printing method for your custom apparel can feel overwhelming, but we're here to help make the process easy. Whether you're leaning towards DTF for its versatility, silkscreen for its bold simplicity, or sublimation for high-performance fabrics, our team can guide you to the best option based on your needs.

If you're unsure which printing method suits your design or the type of apparel you're interested in—whether it's a cotton, polyester, or microfibre t-shirt, polo, or uniform—we invite you to send us your logo. We'll evaluate it and suggest the most suitable printing technique based on your preferences.

Contact us now and we'll be happy to provide a custom quotation for your project, including options for printing or embroidery. Let us help you create standout custom apparel that reflects your brand or event perfectly!